LandGlass is proud to continue its partnership with Transparent Design, the largest flat glass processor in Romania, in their commitment to delivering high-quality glass products. Since its founding in 2005, Transparent Design has been a leader in the industry, consistently investing in advanced technology to enhance production capabilities.

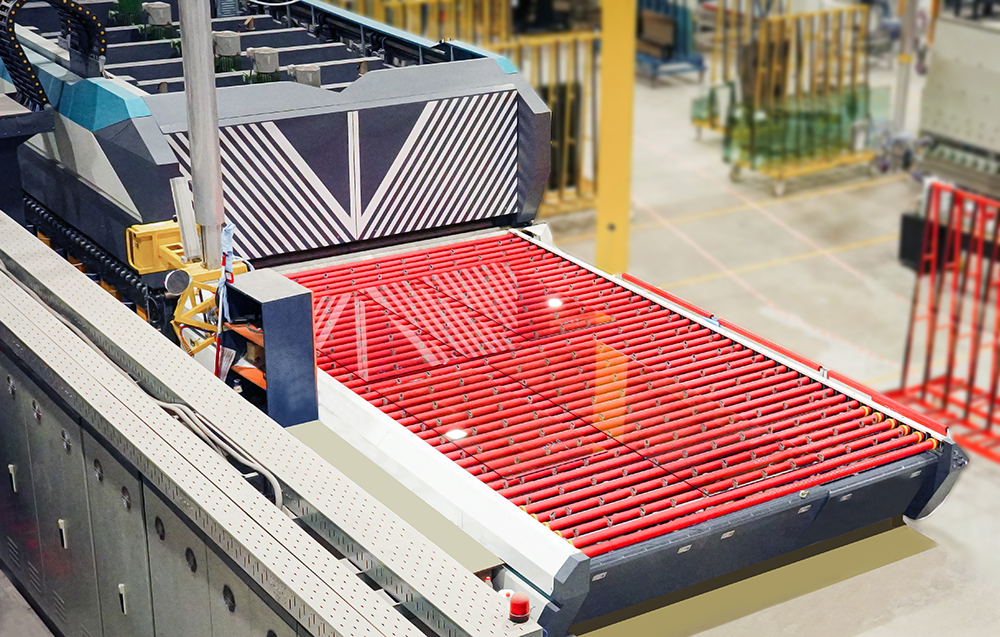

Between 2021 and 2024, Transparent Design selected three LandGlass UltraJet tempering furnaces to meet their growing production demands. In 2021, they installed the UltraJet A3260U, a machine capable of tempering glass sizes up to 6000 x 3300 mm with thicknesses ranging from 5 to 19 mm. This was followed by the installation of the UltraJet Plus Bottom SuperAir in May 2022, a great furnace designed to temper glass up to 5000 x 2400 mm with thicknesses between 3.2 and 19 mm, and a minimum size of 150 x 300 mm. By February 2024, the third furnace, the UltraJet LD-A3050U, was fully operational, boosting Transparent Design’s tempered glass output from 1100 sqm to 1600 sqm per 8-hour shift. This furnace is capable of handling glass sizes up to 5000 x 3000 mm and thicknesses ranging from 5 to 19 mm, further solidifying its position as a leader in Romania’s glass market.

Excitingly, the fourth LandGlass glass tempering furnace is on its way to Transparent Design, expected to be delivered at the beginning of 2025. This cutting-edge glass tempering machine is designed to handle large-format tempered glass, up to 9000x3210 mm. It features advanced convex and concave bending technology, allowing for the production of glass that perfectly meets the sophisticated aesthetic and quality requirements of modern architecture, making it an excellent choice for high-end projects. In addition, 2 automated bending modules would be added to existing tempering furnaces, significantly enhancing Transparent Design’s production capabilities. With these new equipment, Transparent Design will be able to offer tempered curved glass, covering a diverse range of bending radii (both concave and convex), thanks to modern, computer-controlled equipment. The large-size curved glass with complex bends can be used in applications such as interior partitions, structural facades, balustrades, refrigeration displays, products for the automotive industry, and more.

The glass tempering technology used in LandGlass tempering furnaces at Transparent Design complies with European standards EN 12150 and EN 1863, ensuring top-quality and safety. LandGlass is proud to support their ongoing growth and look forward to continuing our successful partnership.